Exposed CLT and carefully concealed services for new Fisher & Paykel HQ

With the SoundDown™ Legato Acoustic Flooring system, services could run in multiple directions and be concealed inside the floor cavity, allowing for exposed CLT ceilings for the 10,000m2 mass timber building.

The new Fisher & Paykel Appliances Global Headquarters, designed by RTA, features 10,000m2 of mass timber including glulam, LVL and CLT over three floors. Exposed timber plays a key role in the aesthetic of the building; the building’s unique diagrid structure is visible throughout interiors and through the glazed exterior facade, and other mass timber elements left exposed, bringing warmth to the interior. With exposed timber ceilings came the challenge of incorporating services between floors — a challenge that SoundDown™ met with the development of the Legato Acoustic Flooring System.

“On this project there were a lot of services, data conduits and electrical work that needed to run in the building,” says Murray Petherick, Site Manager, Salute Construction. “A lot of the underside of the CLT is exposed, so the designers didn’t want those services running in the ceiling cavity like they would in most builds.”

The original flooring specification featured a 90 x 45mm batten on an acoustic block which would allow services to run beneath the floor parallel to the batten. This proved to be restrictive when it came to designing in the significant number of services the building required — a complex combination of electrical wiring, data cables, plumbing and ventilation which needed to run in multiple directions. The design team approached Build Anatomy for a more flexible solution, and in response Build Anatomy developed the SoundDown™ Legato Acoustic Flooring system.

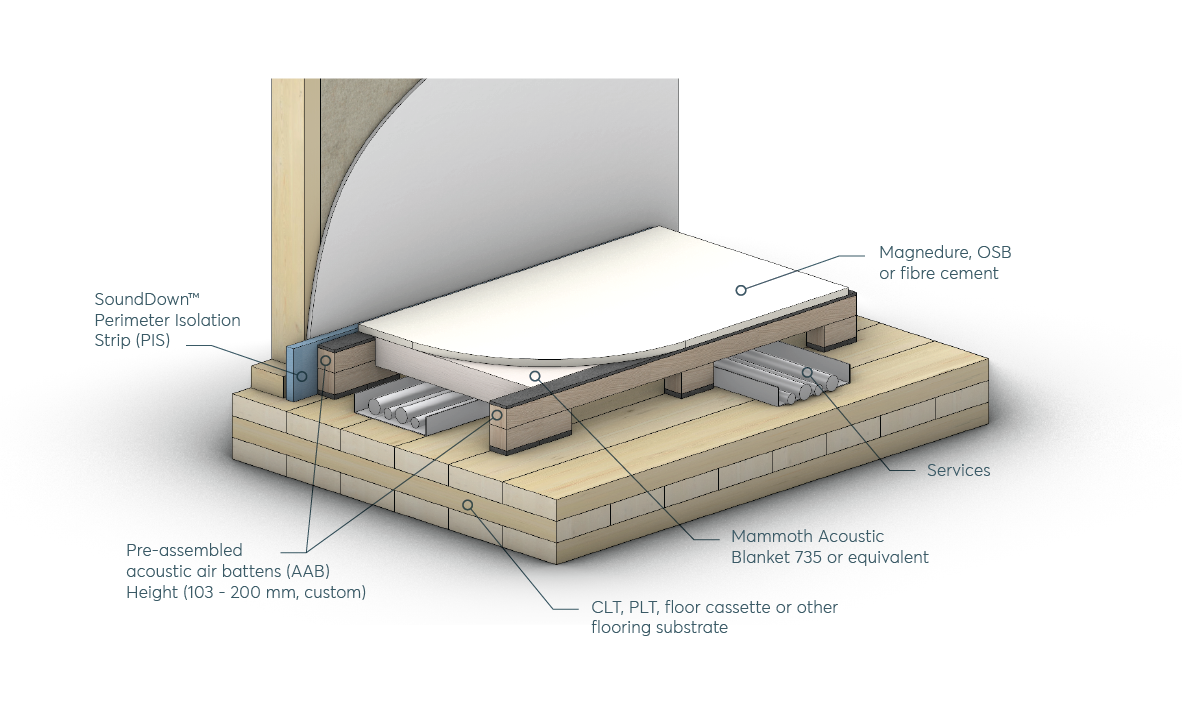

The SoundDown™ Legato system features pre-assembled, castellated air battens (PAB) which are loose-laid over the flooring substructure to create a service cavity of 42 - 140mm in height depending on project requirements. The system allows services to run both parallel and perpendicular to the batten at any point, without needing to notch out the batten, providing greater flexibility in design and install.

Once services have been installed, the cavities are filled with an insulation layer of Mammoth Acoustic Blanket 735, and topped with a fixing layer of Magnedure 19mm MgO board. This results in an acoustic flooring system that achieves tested performance up to STC 66dB and IIC 60dB.

The Build Anatomy team provided support throughout the project to ensure the system would handle any design challenges — which included the sheer size of the project at just over 6000m2, the curved floor plan of the building, and meeting fire requirements.

“It's the first time I’ve ever worked with this product. If there’s been any design issues they’ve come back with input from architects and engineers to get the right detail,” says Murray. “The building has got a lot of curves — it’s designed to mimic a heart shape, so it’s got a big oasis internally that’s completely isolated inside the building itself. Putting the flooring to a curve is quite a challenge when dealing with a batten system, so we had a few little issues around that which the team helped us with. It’s been quite impressive how much input the Build Anatomy team have had, coming through on site on a regular basis assisting the design team.”

One key challenge when incorporating the raised acoustic flooring system was ensuring correct performance of fire cells. To meet this challenge, Build Anatomy provided their SoundDown™ In-Floor Fire Stops. This prefabricated fire-stopping batten is installed beneath the fire door threshold, to maintain continuity of the firecell.

The Build Anatomy team also assisted with custom battens for the building’s gym which had a higher weight load requirement. To ensure the floor could withstand heavy weights being dropped, they developed and tested a custom 4.7 kilonewton point load batten specifically for that space.

The SoundDown™ Legato system was straightforward to install, with a mock-up run helping all parties understand the system and how it would fit in with other elements of the build. “For the services, everything has to work in the module that they’re given with the batten system,” says Murray. “We had a mock-up run-through of the first zone. All services had a chance to work with it, see what it was capable of, and from there it's been a good process. It’s a very practical product.”

Ultimately, Build Anatomy has contributed smart design solutions for the flooring of Fisher & Paykel HQ. The development of SoundDown™ Legato enabled CLT ceilings to remain exposed, and provided the flexibility needed to run services in multiple directions beneath the floor without adding complexity to the project. And to top it off, the system created significant time and cost savings compared to the original specification.

“We were more than happy with the product and process,” says Murray. “The final result has been amazing, I couldn't wish for anything better.”

Get in touch with us to learn more about our products for mass timber projects.

SoundDown™ Legato Acoustic Flooring System